What is a wind turbine.

Functioning and size

The wind turbine, gentle giant that turns wind into clean, renewable, safe, abundant electricity, it is by now a familiar and widespread presence of our natural landscape.

They used to be called windmills. Now they are wind turbines. One, two, no more than three blades rotating, slow, generous, with every breath of wind. We’re getting used to seeing them on ridges of hills and mountains, off the North Sea or, in the case of smaller turbines, in agricultural fields and on top of buildings, but there are different and surprising shapes and sizes.

Here’s how the most advanced and modern machines turn wind into expendable electricity, propagated on the national electricity grid, all the way to our home.

There are many different types of turbines, on different pylons and of the most disparate size, from 2 meters in diameter of domestic turbines to 164 meters of the largest turbine in the world, the titanic Mhi Vestas V164 from 8MW.

The wind has always been a driving force that accompanies humanity, from sailboats to Dutch mills. Wind energy has always been the use of kinetic energy of air converted into mechanical energy through the use of aeromotors, for example, for handling, grinding and crushing materials, or converted into electrical energy, continuous or alternating, through the use of wind turbines – i.e. wind generators – or wind turbines.

Wind turbines are, of course, installed preferably in places that provide adequate wind conditions, hills or mountain ridges, or in the open sea (in this case it is called offshore wind). Normally the wind turbines are implanted in groups, wind farms, so as to take advantage of geographical areas from particularly favorable conditions and to be an appreciable nucleus of electricity production to be connected to the national electricity grid.

Very interesting is the frontier of wind integrated into architecture, with some spectacular realizations on modern skyscrapers and historical monuments. In fact, the Eiffel Tower has been refurbished in a sustainable way thanks to the installation of two vertical wind turbines that produce renewable energy.

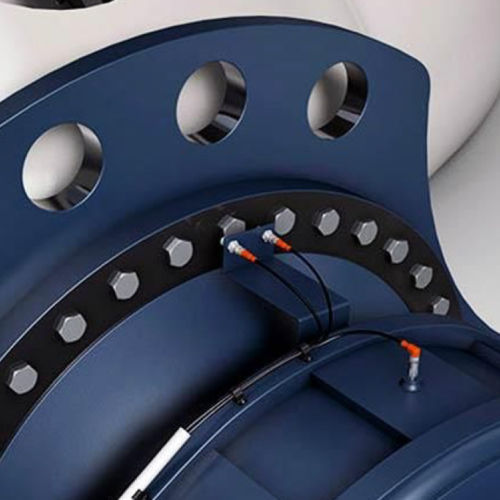

The components of a horizontal-axis wind turbine

Like an airplane propeller, the wind causes the blades to move anchored to the hub to which the rotor is attached.

The rotor consists of a hub on which the blades are fixed.

The blades are made of fiberglass and composite materials.

Two-bladed rotors are less expensive and run at higher speeds. However, they are noisier and subject to more vibration than three-bladed models. Between the two, the energy yield is almost equivalent. Rotors were also made with a single shovel, balanced by a counterweight – at the same conditions, these rotors are even faster than bipalas, but have slightly lower energy yields. There are also rotors with numerous blades, up to twenty, but these are used for direct drive of machines, pumps. Rotors with “mobile” blades were also developed: varying the tilt of the blades according to the wind speed the amount of electricity produced by the aerogenerator can be kept constant. And begin to see wind turbines of great designers or in the shape of a hummingbird wing.

Then there is a gear spin multiplier that is used to transform the slow rotation of the blades in a faster rotation of the shaft at the typical speed of an alternator (3,000 – 3,600 rpm) that generates the alternating current.

The gondola (or boat) that contains this relatively basic apparatus is anchored to the yached system, a servomechanism that is used to maintain the most continuous alignment possible between the rotor axis and the wind direction.

The support tower can be tubular or trellis, stuck in the ground with its foundations.

Electricity production is regulated by control systems, software and the ground processing box, with the connection to the grid. The aerogenerator operates according to the force of the wind; under a certain speed the machines are unable to start; for the start-up to be there, the speed must reach a minimum insertion threshold, different from machine to machine, but from about 4-5 meters per second (15-18 km/h).

The gondola (or boat) that contains this relatively basic apparatus is anchored to the yached system, a servomechanism that is used to maintain the most continuous alignment possible between the rotor axis and the wind direction.

The support tower can be tubular or trellis, stuck in the ground with its foundations.

Electricity production is regulated by control systems, software and the ground processing box, with the connection to the grid. The aerogenerator operates according to the force of the wind; under a certain speed the machines are unable to start; for the start-up to be there, the speed must reach a minimum insertion threshold, different from machine to machine, but from about 4-5 meters per second (15-18 km/h).

The power of a wind machine is the greater the stronger the wind, the bigger and more efficient the blades and the denser the air (e.g. at sea level). Where, at high altitude, the air is rarefied, larger blades are needed. During operation the “nominal” wind speed is the minimum that allows the machine to provide the project power (10-12 m/s, 35-45 km/h, for a few hundred kW for medium-sized machines). At high speeds (over 20-25 m/s, 72-90 km/h) the aerogenerator stops for safety reasons.

Multi-megawatt-class wind turbines have rotation speeds between 18 rpm and 25 rpm depending on the size and type of the aerogenerator. I mean, we’re talking about one lap every three seconds.

The blades, therefore, rotate very slowly, a reality quite different from the idea of gigantic fans that some imagine.

The size of wind turbines

If you wish, you can also buy a domestic wind turbine. There are very small microturbines on the market, which can be placed on the roof of houses. Powers from 3 to 10 kW, footprint of a few meters (even just 2) and they also get to have original conformations: 5 blades, or alternative and imaginative design vertical axes (such as the wind turbine that resembles a tree) or even wind turbines without shovels.

The world’s largest working turbine is the 8MW Mhi Vestas V164, each of its three blades 80 metres long and weighs 33 tons. 8 MW of energy means that, on its own, one of these turbines gives electricity to 7,500 homes. 220 meters high (it is more than two-thirds high than the Eiffel Tower) and 5,900 tons in weight (more than 10 Airbus 380 fully loaded airplanes). Its 80-metre rotating blades “sweep” an equivalent area to three football pitches. One of similar size is coming, the Adwen AD-180, born from a joint venture between Gamesa and Areva, whose blade will be 88.4 meters, whose shovel will be 88.4 meters, 10 percent longer.